Our history and achievements

Construction of the Selenginsky pulp and cardboard mill began in 1959 at the site where the construction of a pulp and viscose mill was carried out earlier (from 1956 to 1959).

The choice of the site for the construction of the plant on the Selenga River was due to the availability of sufficient timber resources in the republic, the absence of timber consumers on site, a developed transport network, available building materials and the proximity of a coal deposit.

In April 1959, the State Planning Committee of the USSR and the Council of Ministers of the RSFSR made a proposal to the Council of Ministers of the USSR to change the profile of the Selenginsky Combine: the production of only containerboard. Thus, the necessity was justified to build an enterprise in the Baikal basin - a utilizer of sawmill and woodworking waste.

The plant was built in extremely difficult conditions associated with the seismicity of the zone (up to 9 points). Only on the main production building, excavation work was carried out for a foundation pit of 289446 m3, piles were driven under the foundation - 21174 pieces, 11394 tons of metal structures were mounted, 1092 tons of aluminum panels were laid, 52735 m2 of glazing were performed, the figures given speak not only about the huge scale of construction and installation work, but also how much labor, energy, perseverance the builders put into the creation of the plant. The construction was announced by the All-Union Shock Komsomolskaya.

During the construction, the design assignment was repeatedly corrected, a number of examinations took place. The geographical location of the enterprise has caused close attention to it from the side of environmentalists. The requirements for environmental measures were constantly increasing and this could not but affect the increase in the construction time of the plant.

The workshops of the plant were put into operation as soon as they were ready. The electrical repair shop and central mechanical repair shops were the first to start operating - 1967.

In 1971, by order of the Ministry of the Pulp and Paper Industry of the USSR, the design assignment of the Selenginsky Pulp and Paper Mill, adjusted by Sibgiprobum, was approved with the main indicators:

- pulp for cooking 297 thousand tons per year,

- containerboard - 280 thousand tons per year.

On June 30, 1971, the State Acceptance Commission commissioned the first stage of the TPP, and in August the first generator gave an industrial current.

On April 25, 1973, the board-making machine K-07 was tested under load on imported Baikal cellulose and the first product was obtained - commercial cellulose.

According to the act of the State Commission, the volume of containerboard production was determined at 140 thousand tons.

On June 7, 1973, the first pulping was carried out and the entire technological chain of the mill for the production of cardboard was involved.

On June 30, 1973, an act of the State Commission was signed on the commissioning of the first stage of the plant in the amount of 145 thousand tons of pulp for cooking and 140 thousand tons of cardboard per year. This date became the birthday of the Selenginsky pulp and paper mill.

1973-1974 years - the years of commissioning, years of hard work, when specialists literally did not leave the shops for days, the years of the formation of the plant's collective, the improvement of technologies.

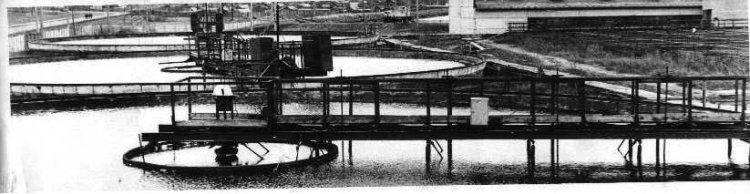

1974 was the year of full development of the technology of biological, chemical, mechanical treatment of industrial effluents, which resulted in a unique in its kind work of the treatment complex structures capable of minimizing the harmful impact of runoff on the ecosystem of Lake Baikal.

In January 1975, K-2 cardboard was received, and in January 1976, the supply of products for export began.

On December 31, 1976, a plant for processing by-products from pulping into tall products was put into operation. Currently it has the name - Workshop for the production of wood chemical and paint products.

In 1975-1977, together with the employees of the Astrakhan VNIIB, the mode of pulping and obtaining cardboard for flat layers of corrugated cardboard on mixed wood with the addition of 50% larch was worked out.

The basis of the cardboard production at the plant and its integral part is the cooking production, which produces 95 thousand tons of sulphate unbleached pulp per year.

The plant has ten digesters with a capacity of 140 cubic meters each.

In October 1977, KDM-2 was put into operation, its products are wrapping paper and paper for corrugation, and the production of K-1 cardboard was started.

The plant for processing by-products from pulping into tall products was commissioned in 1977 and is designed to process crude tall oil from the Selenginsky pulp and paper mill and the Baikalsky pulp and paper mill. The main technological equipment of domestic production.

On October 11, 1977 at KDM-2 the first products were received - wrapping paper and paper for

corrugation, and then the production of K-1 grade cardboard was started.

At the end of the seventies, among the main tasks facing the collective of the enterprise were the fulfillment of the state plan and the improvement of the quality of the products.

In 1980, the plant for the first time fulfilled the state plan, and since 1987 it has been consistently fulfilling the plan, including the supply plan under contracts.

At the end of the seventies, one of the main tasks facing the enterprise's staff was the fulfillment of the state plan and the improvement of the quality of products.

In 1984, a site for the production of paints and varnishes was opened. Its first product is tall oil varnish. In 1989, the production of PF-283 varnish began; PF-053 and PF-223 enamels; PF-266. The workshop for the production of wood-chemical and paints and varnishes produces rosin, fatty tallic acids, distilled tall oil (DTM), varnish, drying oil, enamels. The workshop works with high profitability, produces high-quality products that are in demand on the market.

In 1980, the plant for the first time fulfilled the state plan, and since 1987 it has been consistently fulfilling the plan, including the supply plan under contracts.

1980-1990 年是企業的穩定期。 在此期間,進行了大量工作 - 將紙板機現代化並將其轉移到合成網,以減少灰塵和氣體排放,引入世界實踐中沒有類似物的封閉水循環系統。

1990 年 8 月 1 日,該工廠停止向色楞格排放工業廢水。

New economic conditions and a drop in demand for containerboard forced the mill to take the path of production diversification. A course was taken for deeper processing, which resulted in the construction in a short time and the launch of a corrugated packaging workshop with a capacity of 30 million m2 / year with a further increase in capacity to 60 million m2 / year.

On October 21, 1992, the corrugated packaging workshop released its first products. The new production facility made it possible to process on-site a significant part of the produced cardboard, leave it for further processing and produce the final product - corrugated containers. This, in turn, made it possible to increase sales of products, significantly expand its range.

In 1992, a corrugated cardboard production line ZBJ-1600, a slitting machine No. 1, a stitching section, a waste disposal unit, mastered the production of starch glue.

October 1992 - in connection with the economic reform, the plant was transformed into an open joint-stock company "Selenginsky-cellulose cardboard plant".

In May 1993, the production of lumpy gaskets was opened, a line for the production of boxes No. 2 was launched.

In order to put the work on the sale of manufactured products to the proper level, in May 1993 a shop for acceptance and shipment of finished products was organized.

In 1994, a line for the production of boxes No. 3, PVS No. 2 was launched, a production site for components for corrugated packaging was organized.

In 1994, a line for the production of boxes No. 3, PVS No. 2 was launched, a production site was organized.

In 1995, the production of cardboard-winding drums was mastered, a line for the production of boxes No. 4 was launched, a line for the production of corrugated cardboard - LSGKP, flat nibbling machines.

October 1995 - the Selenginsky customs point was opened to service the goods of the plant, following the border.

of accessories for corrugated packaging.In 1996, FPT launched a line for the production of boxes No. 1 and two rotary cutting machines of the "Reverse" type. The same year was the period of the formation of a new workshop - printing. The task of this workshop is to meet the needs of the plant for printed products for various purposes, information and advertising design of the manufactured packaging.

In 1997, KDM-1 received a new product - sack paper with indicators that meet the requirements of GOST.

Currently, the container production workshop produces any types of corrugated board products, has corrugated units, four processing lines and one printing and die-cutting machine, rotary cutting machines. There is a section for the production of complex die-cut corrugated packaging and a section for the production of lumpy gaskets.

Since its opening, the workshop has been gradually increasing its production capacity, increasing the volume of production and its assortment.

May 1997 - a logging site was organized, which in September grew into a logging workshop.

The economic crisis of the 90s destroyed the raw material base of the plant and therefore the enterprise had to form its own raw material base.

August 1997 - the section for the production of paper bags on the raw materials produced by KDM-1 began to work.

The organization of this new business became possible thanks to the investment support of the Fund for the Implementation of the Federal Program for Socio-Economic Development of the Republic of Buryatia.

The logging shop has its own fleet of logging and logging equipment, has a powerful material and technical base and provides a third of the production demand for raw materials.

Timber base of the plant - coniferous and deciduous forests of Buryatia, Chita, Irkutsk regions. Raw materials for the plant are one of the dominant components of production and a stable flow of raw materials, in turn, is a condition for stable production. JSC "Selenginsky pulp and paper mill" is consistently increasing the growth in the volume of timber harvesting on its own.

In 1998, a workshop for the production of coated cardboard was opened, and the production of a box for a cake was also mastered here.

2000 - start-up of a paper machine. In the same year, the production of paper bags was founded.

2001 - polypropylene production started operating.

In 2001, the modernization of KDM-2 was started. Constant work in recent years to improve quality indicators has yielded results. In 2003, the volume of K-1 grade cardboard amounted to 85% of the total output.

May 2002 - managers of LPK "Continental Management" entered the management of the enterprise.

2003 - a phased replacement of the washing station began in the brewing and washing shop.

2004 - new chip sorting was installed in the woodyard.

2005 - KDM-1 received K0 cardboard. By August, its share was 10% of the roll-up.

In 2005 the plant worked steadily, at a good level, there was an increase in economic indicators to the level of 2004, the profitability of the plant's products increased. Along with quantitative successes, progress has been made in the field of quality. In order to exclude abrasion of products during transportation, the corrugated packaging workshop mastered the packaging of products into pallets, and a new type of product was also mastered here - a bag with a laminated coating.

The building of cutting capacities continues in the WPC, where the MRN-100 chipper is installed.

Certain successes have been achieved in brewing production. Two new pressure filters were put into operation, significant savings in heat energy consumption were achieved. In August, the installation of the "NOSS" sorting machine of the Finnish company "METSO" was completed in the HCV.

2006 went down in the history of the mill as the year of records, the maximum level achieved by the mill in the production of cardboard. The increase in production volumes amounted to 12.3% against the 2005 level. But not only quantitative characteristics have become a source of pride for the work collective of the plant based on the results of work in 2006.

Serious successes have been achieved in the field of product quality. The production of cardboard grades K-1 and K-0 totaled 98% of the roll. This literal quality breakthrough has been seen in the consumer market. Cardboard for flat layers of corrugated cardboard, grade K-0, produced by OJSC Selenginsky CCM, was awarded the Big Gold Medal at the Novosibirsk exhibition-fair “SIBUPAK-2006”.

2007. The production of cardboard for flat layers of corrugated cardboard of the KS brand (Selenga-liner) has begun. A large investment project was approved for the container production workshop.

2008. Modernization of the equipment park of the container production workshop. Introduction of new equipment. The production of P-92 laminated wrapping paper has been mastered.

January 2008 marked the beginning of the CPT modernization project. A slitting machine for a corrugator was delivered to the mill and put into operation.

June 2008. New equipment has been introduced into the work of the container production workshop - a semi-automatic two-head stitching machine made in Taiwan.

On December 23, 2008, a record annual number of tons of cardboard for flat layers of K1-150 corrugated cardboard was produced - 100 thousand tons.

March 2009. Commissioning of new equipment for the container production workshop.

April 2009. A new type of product was received at the paper container section of the CPT - a bag with a coated coating.

May 2009. After a long shutdown due to the lack of imported Baikal raw materials due to the shutdown of the BPPM, the workshop for the production of wood chemical products resumed its work.

Also in 2009, the modernization of the corrugated unit LSGKP was carried out with the replacement of the main units with computerized equipment of Taiwan production and the installation of a corrugated press, which allows the production of 5-layer corrugated cardboard.

High-speed computerized processing lines with multicolor printing for the production of corrugated boxes and corrugated containers of complex die-cutting were installed at the processing section of the packaging workshop. An automatic line for strapping and wrapping pallets in stretch film was put into operation.

November 15, 2012. 5 proposals of the Selenginsky Pulp and Paper Mill were included in the top-100 best rationalization proposals of the Russian industry.

April 19, 2013. The products of Selenginsky Pulp and Paper Mill won first place in the competition "The best goods and services of Eurasia - GEMMA".

October 15, 2013. Selenginsky pulp and paper mill commissioned a new chimney of the TPP.

November 2013. The enterprise is in a difficult economic situation, the team is fighting to preserve it, mass rallies have been organized in the village and on the territory of the plant.

December 2013. With the support of the President of Russia Vladimir Putin and the government of the Republic of Belarus, the owner is being changed.

January 2014. A new period in the life of the plant began, a period of restoration of lost positions, further development and movement forward.

October 29, 2015. Selenginsky pulp and paper mill for the first time in Russia carried out the transportation of private labels (tallow crude oil) in flexitanks.

January 29, 2016. Selenginsky pulp and paper mill completed the first stage of work related to the modernization of the cardboard machine. Within the framework of the project: a new generation hydraulic headbox with DCS automated control system was installed; a new short circulation system was installed using welded wire type slotted screens; HONEYWELL QCS automated quality management system has been implemented.

August 2016. The overhaul of soda recovery boiler No.2 was completed. During the overhaul, all the main elements of the boiler were replaced, including the furnace screens, and a new electrofilter was installed. The commissioning of SRK No. 2 will reduce the negative impact on the environment and increase the reliability of energy technology equipment.

September 2016. Modernization of the wet end of the board machine has been completed. The implementation of the project made it possible to stabilize the concentration of pulp before feeding to the grid table, to improve the process of dehydration of the pulp, as a result, to improve the quality and consumer properties of containerboard.

August 10, 2017. Selenga Pulp and Paper Mill has implemented an international system of safety and quality of packaging and packaging materials BRC.

September 14, 2017. Selenginsky Pulp and Paper Mill received the status of an authorized economic operator.

October 2017. Within the framework of a large-scale modernization project in the workshop for the production of containerboard on cardboard machine No. 1, the following has been completed: two mills have been installed in the grinding and preparatory department; three presses were replaced; a soft calender is additionally installed in the press section; a new size press with a glue preparation and supply system was installed; a calender with adjustable bombs was installed; the roll-over was replaced; the slitting machine was modernized; a new packaging line for finished cardboard was installed; the direct current electric drive was completely replaced by an electric drive with digital frequency regulation.

A new line for sorting pulp was installed in the cooking and washing department. Two concentrators were replaced in the evaporation shop. A major overhaul of the turbine generator No. 1 was carried out at the TPP of the plant. The system of automatic control and metering of heat energy has been launched.

2018. TPP. The beginning of the installation of a biofuel boiler, which will allow processing 20 fine wood waste per hour.

May 11, 2018. Selenginsky Central Control Commission became the founder of the first school republican Olympiad.

June 30, 2018. The Selenginsky pulp and paper mill in honor of its anniversary presented the workers with a grandiose holiday!

A significant date - the 45th anniversary of the Selenginsky pulp and paper mill became an amazing, bright and beautiful holiday for the team of the city-forming enterprise, residents of the village and the region. In honor of the anniversary of the enterprise, a festive program was organized, which included a whole range of events: a series of publications in the regional newspaper "Baikalskiye Ogni" about the labor dynasties of the pulp makers, some of which already have three generations, was released. jubilee film about the plant, workers were awarded cash prizes for their seniority, a two-day celebration was organized for workers and residents of the village with a gala concert, a procession of workers and veterans of the plant in a festive column, interesting events at the Trud stadium, attractions,

theatrical performance "Happy Birthday, Combine!" In the evening at the stadium there was a disco with the participation of Russian pop stars and Buryat artists. The anniversary ended with a festive fireworks accompanied by a dynamic, beautiful anthem of the plant!

2019. Large-scale work continues on the technical re-equipment of the enterprise. The plant is being replenished with new modern equipment.

May-July 2019. Installation of a fiberglass chimney shaft of SRK TPP is being carried out instead of the old metal one.

July 30, 2019. Selenginsky pulp and paper mill won the competition "The best taxpayer of the Republic of Buryatia" at the end of 2018.

2019. The industrial production of a new type of product - paper for fluting from virgin cellulose fiber (KRAFT-FLUTING) - with high quality indicators has begun.

February 2020. A biofuel boiler was put into operation, which makes it possible to utilize wood waste from the plant and other enterprises, which significantly reduces the environmental load on the environment.