About

-

1,700 employees

work at the plant

-

110,000 tons

annual production of cardboard and paper

-

60 million m2

corrugated board production capacity per year

-

400 ha

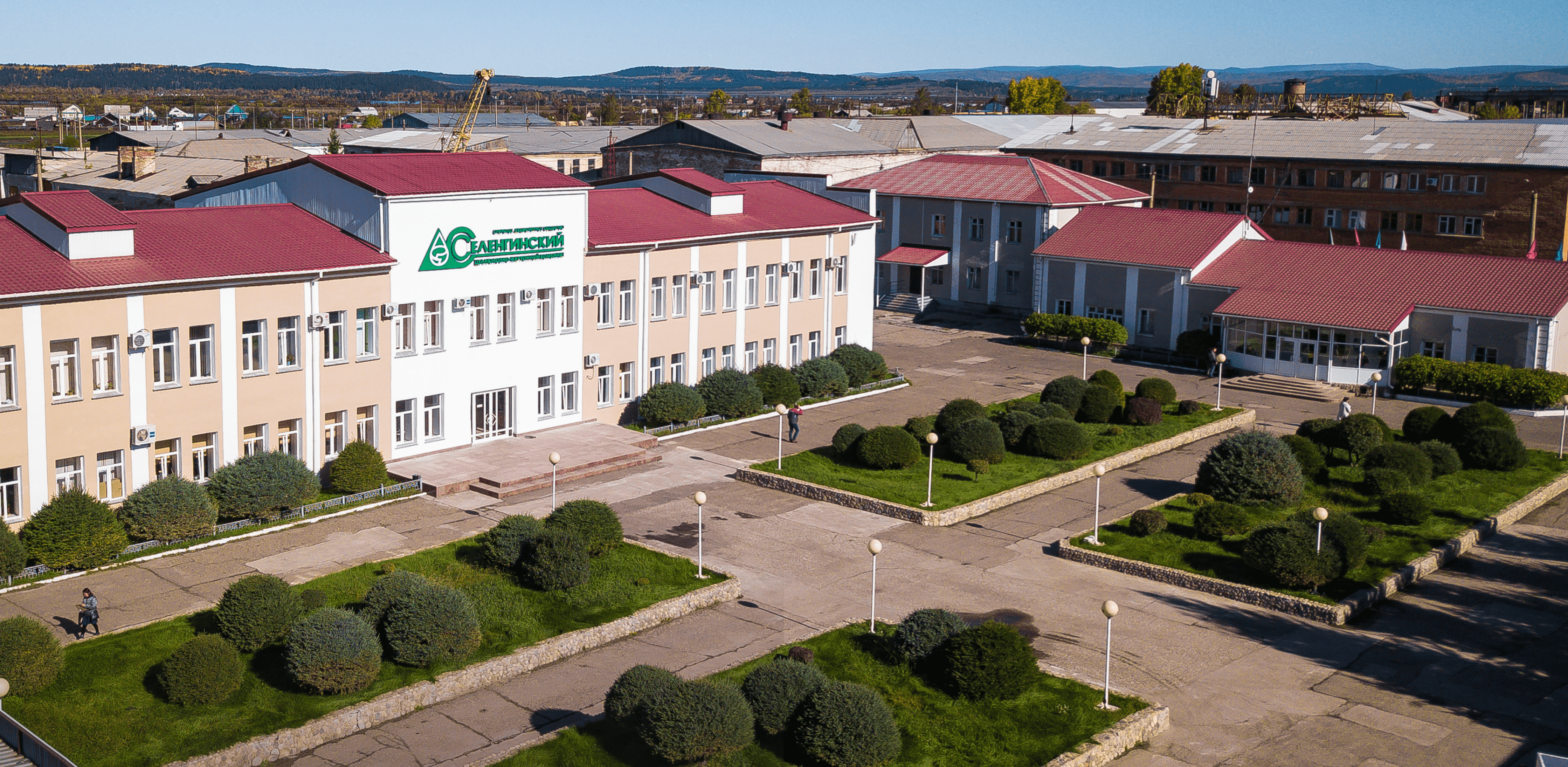

plant area

-

4500 tons

annual release of wood chemical products

Our production

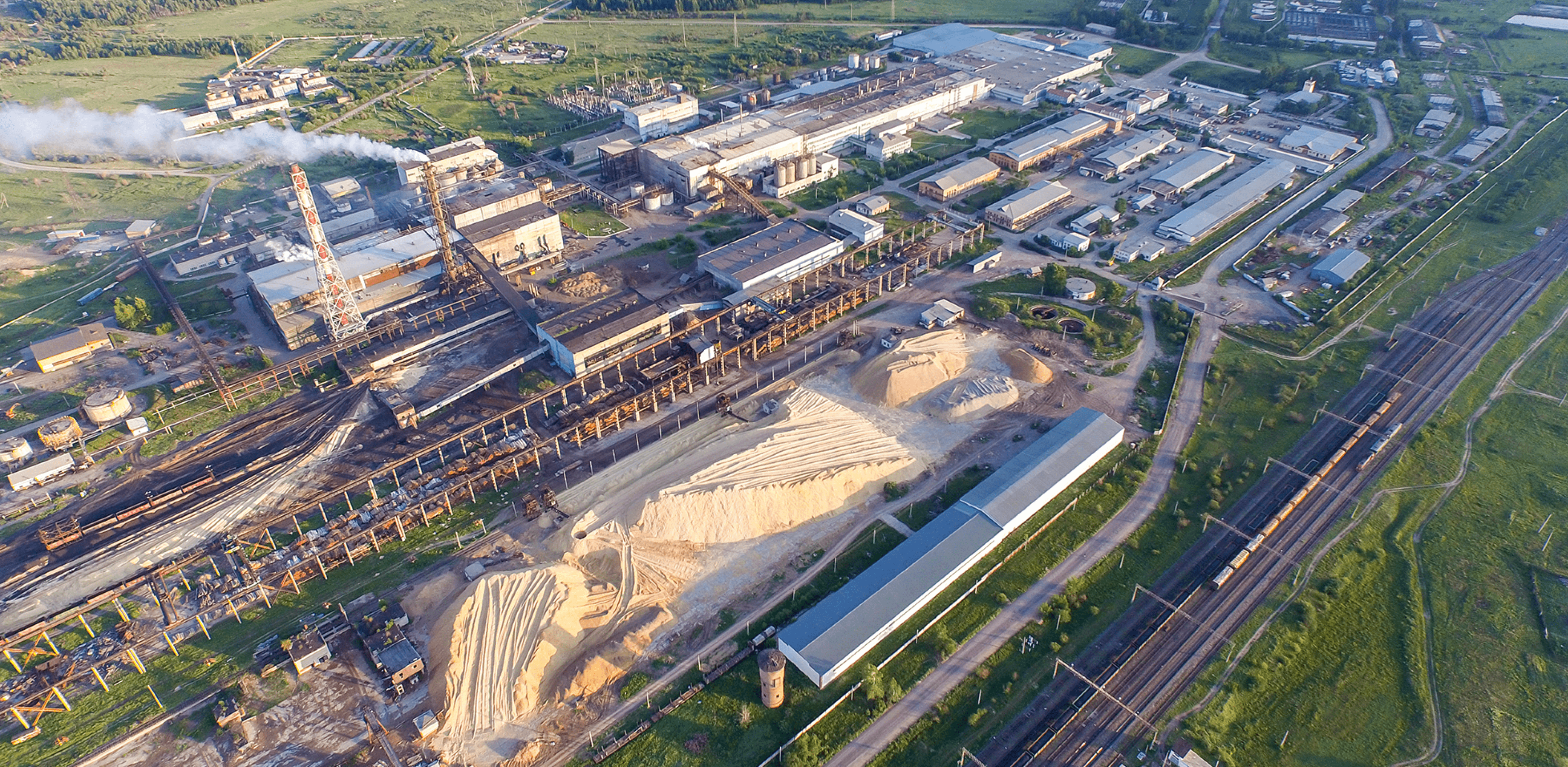

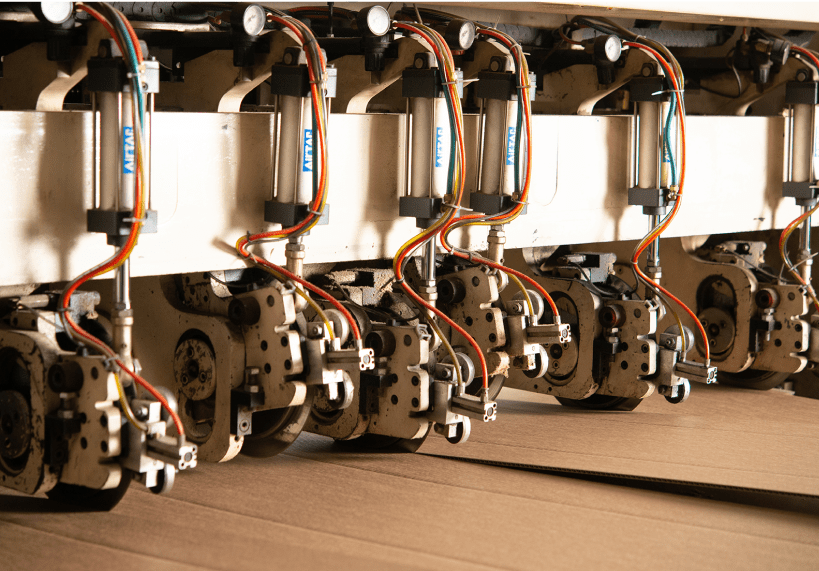

Selenginsk pulp and cardboard mill specializes in the production of flat layers of corrugated cardboard, corrugated board products and wood chemical products.

Go to catalogSales geography

OJSC "Selenginsk pulp and cardboard mill" supplies its products to food enterprises, chemical, construction, medical and many other industries in Russia and foreign countries. 9 countries international partners - China, Mongolia, India, Afghanistan, neighboring countries.

-

The plant is located near the federal highway M-55 "Irkutsk-Ulan-Ude-Chita" and carries out the shipment of products by all types freight vehicles.

-

OJSC "Selenginsk pulp and cardboard mill" has its own railway station, connected with the Trans-Siberian Railway, has its own rolling stock.

The plant includes

- Containerboard workshop.

- Workshop for the production of packaging (production of corrugated cardboard, corrugated packaging, corrugated packaging complex cutting).

- Workshop for the production of wood chemical products.

- Woodyard.

- Brewhouse.

- Evaporation shop.

- Workshop for causticizing and reclaiming lime.

- Workshop of instrumentation and automation.

OJSC "Selenginsk pulp and cardboard mill" has a well-developed repair base and many years of unique experience. Workshops repair team perform work on current and major repairs, modernization and installation equipment enterprises, industrial premises.

The auxiliary group of workshops includes:

- Mechanical repair shop.

- Repair and construction shop.

- Electrical repair shop.

- Heat water supply and sewerage workshop.

- Complex of treatment facilities.

- Railway shop.

- Motor transport workshop.

- Thermal power plant (TPP).

- Communication workshop.

- Printing area.

- Warehouse facilities.

- Catering workshop.

Selenginsk pulp and cardboard mill was awarded many awards and victories at all-Russian and international competitions

The plant has more than half a century of history from the moment the foundation was laid in 1959 to the present.

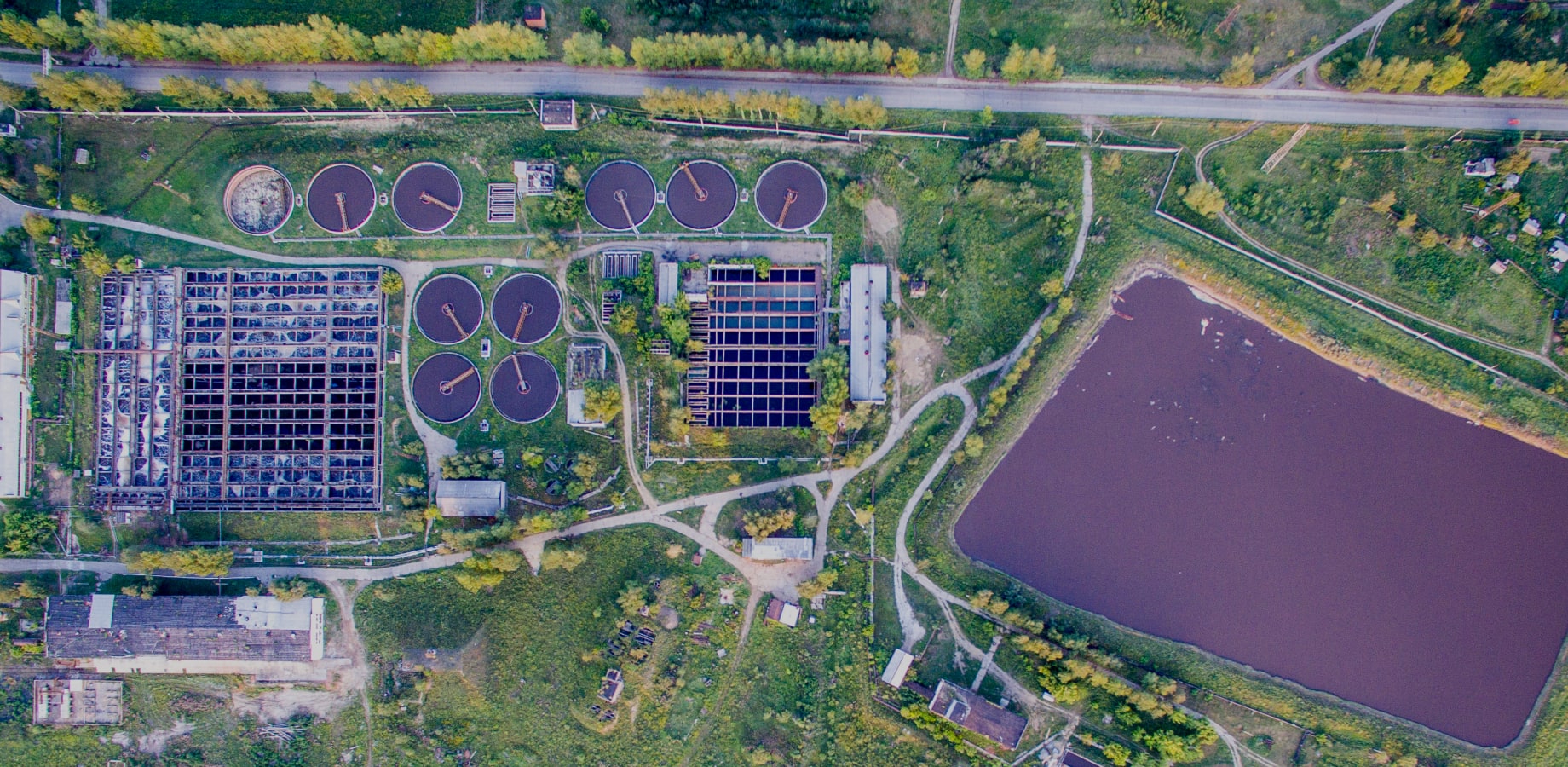

Ecological production

Selenginsk pulp and paper mill - an enterprise located near Lake Baikal, bears social and environmental responsibility, making decisions in the course of production activities aimed at protection environment and ecological safety.

The plant operates without discharge of treated wastewater into water bodies, which reduces the load on nature.

-

In 1990, for the first time in world practice, a patented closed water circulation system was launched at the enterprise, which completely eliminated the discharge of industrial effluents without reducing the quality of products. A powerful complex of treatment facilities provides triple chemical, biological and mechanical treatment.

-

Since 1977, a sanitary-industrial laboratory has been operating at the plant, which is engaged in monitoring emissions from production to treatment facilities. Subsequently, her responsibilities began to include monitoring the air environment in the sanitary protection zone of the plant.

-

In 2010, the Selenginsky Mill became the winner of the All-Russian competition “The Best Russian Enterprises” in the “Environmental Responsibility” nomination, being the only pulp mill in the world operating in a closed circuit under closed water circulation conditions.

-

Control of technological processes, quality of raw materials, semi-finished products, finished products is carried out at all stages of production. The quality of our products can be called our “national idea”. For many years of work, thousands and thousands of cars of corrugated products, tons of wood chemistry, billions of square meters of cardboard and paper have been tested for quality.

Teamwork allows us to work successfully in the market, to be competitive and achieve your goals

Our company values its employees and focuses on the development and professional growth of personnel through introduction of incentive systems, corporate training, compliance with labor protection and social guarantees.

We are convinced that conscientious, proactive and qualified employees who share the goals of the company and responsibility for the result is our greatest value.

We highly appreciate your attention and trust in us

Of course, we are proud of this trust, we increase it, therefore we are constantly modernizing production, we aim each link of our business at the most accurate understanding and fulfillment of the requirements of our clients.